2 minute Read

How In-House Manufacturing Strengthens Public EV Charging

First Published: (Last Updated: )

At Trojan Energy, we are committed to making on-street EV charging more reliable, cost-effective, and accessible for local authorities and communities across the UK. Our Flat and Flush® technology is already transforming the way residents charge their EVs, and in 2024, we took a major step forward by bringing all manufacturing in-house to our Aberdeen HQ.

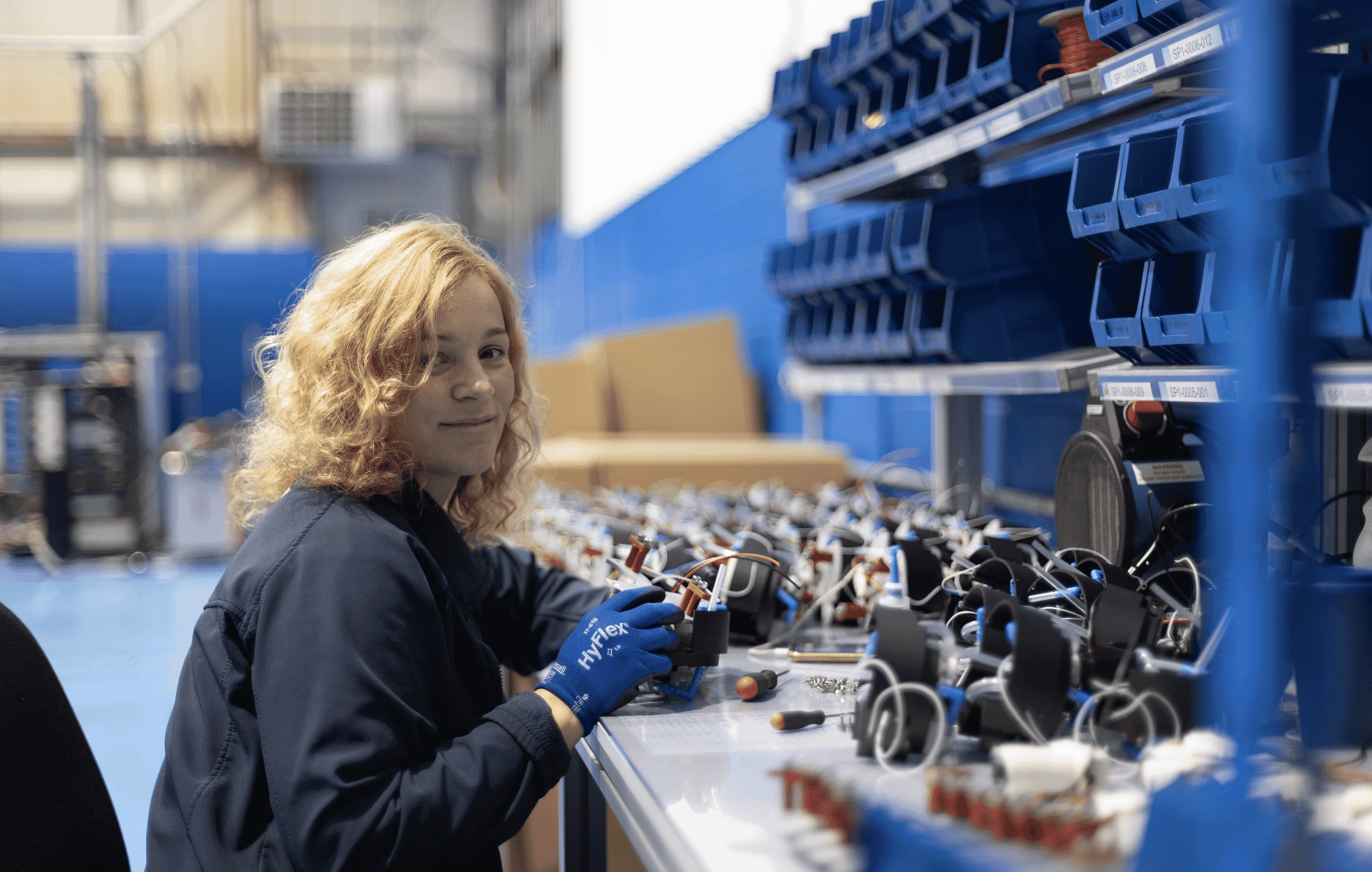

This transition has been a major success for us. Our Head of Manufacturing, Mira Richter, and his team have tackled key challenges head-on, from relocating production lines, phasing out obsolete equipment, refining designs at speed, setting up new stock control and warehouse systems, and bringing in top talent to strengthen our growing production team.

For local authorities, this means better quality, lower costs, and greater supply chain resilience – ensuring that the infrastructure you invest in delivers long-term value.

Driving down costs for local authorities

By manufacturing everything in-house in our Aberdeen HQ – from our base units and feeder pillars to chargers, adaptors, and even printed circuit boards – we’ve eliminated hidden margins and inefficiencies that often come with outsourced production. This direct cost control allows us to offer more affordable EV charging solutions without compromising quality.

For example, by manufacturing a key charge point component in-house, we reduced costs by over 50% – savings that can be passed on to councils looking to expand their charging infrastructure.

Increasing reliability and longevity

A major challenge in public EV charging is ensuring long-term reliability. When manufacturing is outsourced, it can be difficult to control quality, leading to higher maintenance costs for local authorities.

By keeping production under one roof, we oversee every stage – from design to assembly – ensuring consistent quality, fewer defects, and extended product lifespan. This means less downtime, fewer callouts, and more dependable EV infrastructure for local communities.

Faster innovation for smarter public charging

With our manufacturing team working side by side with our engineers, designers, and customer service leads, we can quickly adapt to evolving customer needs. Unlike third-party manufacturers, we don’t need to wait to make changes. This agility helps us stay ahead of evolving EV charging demands.

Supporting local jobs & green manufacturing in the UK

Public sector investment in EV charging is not just about infrastructure, it’s also about boosting local economies and green jobs. Since 2022, our headcount has tripled to 86 employees, with 15 dedicated to manufacturing. Many of our team members have already progressed into leadership roles, reinforcing our commitment to high-quality UK manufacturing.

For local authorities focused on sustainable procurement and economic growth, working with Trojan Energy means supporting skilled green jobs while investing in robust, homegrown EV charging solutions.

Partnering with local authorities for a greener future

By bringing manufacturing in-house, Trojan Energy is delivering high-quality, cost-effective, and scalable EV charging solutions tailored to the needs of councils and communities.

Our in-house approach is a game changer for local authorities seeking affordable, reliable, and future-proofed public EV charging.

We’re closer to our technology, our customers, and our future.